Introduction:-

Laser symbolize as Light Amplification by Stimulated Emission of Radiation. The underline regulation of the optical laser was 1st argue by Einstein in 1917 although the primary industrial optical maser for experimentation was developed around the Nineteen Sixties.

Laser Beam Welding is a combination welding measure in which two metal pieces are consolidated by the utilization of laser. The optical laser radiates are engaged to period between the 2 metal items to be joined. The laser radiates have sufficient energy and when it strikes the metal pieces produces heat that liquefies the material from the two metal pieces and fills the cavity. within the wake of cooling a solid weld is formed between the 2 items.

It is an extremely proficient welding measure and can be robotized with advanced mechanics apparatus without any problem. This welding method is generally utilized in the auto industry.

Working Principle:-

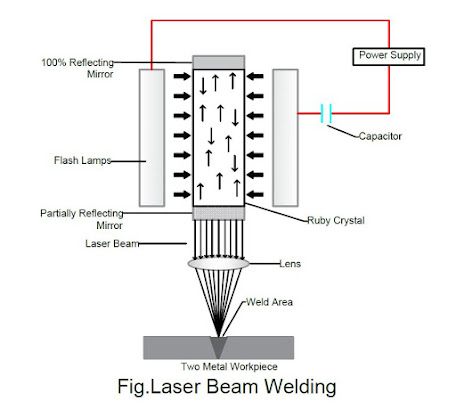

Laser Beam Welding(LBW) may be a fusion connection method that produces jointure of materials with the warmth obtained from a focused beam of coherent, monochromatic light-weight striking on the joint to be welded.

In the LBM method, the shaft is directed by flat optical parts, like mirrors so targeted to a little spot (for high power density) at the work victimization either reflective focusing parts or lenses. it's a non-contact method, requiring no pressure to be applied.

Inert gas shielding is usually utilized to stop the chemical reaction of the liquified puddle and filler metals is also sometimes used.

Lasers that are preponderantly getting used for industrial material process and fastening tasks are the Nd-YAG optical maser and 1.06 µm wavelength CO, laser, with the active parts most typically utilized in these 2 types of lasers being the neodymium(Nd) particle and therefore the and therefore the severally.

Equipment's of LBW:-

The main elements or equipment of laser beam welding are as follows:

- Laser Machine: It is a machine that is utilized to create a laser for welding. The principal parts of the laser machine appear beneath.

- Power Source: A high voltage power source is applied across the laser machine to create a laser bar.

- CAM: It is a Computer-Aided Manufacturing in which the laser machine is coordinated with the PCs to perform welding measures. All the controlling activity during the welding interaction by laser is finished by CAM. It speeds up the welding interaction undeniably.

- CAD: It is called as Computer-Aided Design. It is utilized to plan the work for welding. Here PCs are utilized to arrange the work and the way the fastening is performed on that.

- Shielding Gas: A protecting gas might be utilized during the welding interaction to keep the workpiece from oxidation.

Advantages:-

Following are Advantages of Laser Beam Welding :

- Heat input is on the point of the minimum needed to fuse the weld metal, so heat-affected zones are reduced and work distortions are reduced.

- Time for fastening thick sections is reduced and therefore the filler wires and elaborate joint preparations are eliminated by using the single-pass optical maser fastening desires procedures.

- No conductors are required; fastening is performed with freedom from electrode contamination, indentation, or harm from high resistance fastening currents.

- LBW being a non-contact method, distortions are reduced and gear wears are eliminated.

- The beam is targeted on a little space, allowing the connection of tiny, closely spaced elements with small welds.

Limitation of LBW:-

The Limitation of Laser Beam Welding is as follows:

- Joints should be accurately positioned laterally below the beam and at a controlled position with regard to the beam attentiveness.

- In the case of mechanical clamping of the weld joints, it should be ensured that the ultimate position of the joint is accurately aligned with the beam impingement purpose.

- The maximum joint thickness that may be welded by the shaft is somewhat restricted. so weld penetrations of larger than nineteen millimeters are tough to weld.

- High reflectivity and high thermal physical phenomenon of materials like Al and metal alloys will have an effect on the weldability with lasers.

- An acceptable plasma management device should be used to make sure the weld reliability whereas performing arts moderate to high power optical maser fastening.

- Lasers tend to possess fairly low energy conversion potency, typically but 10%.

Applications of LBW:-

- Laser Beam welding is predominant in the auto industry. It is utilized in the space where huge volume creation is required.

- Small Medical and Jewelry items.

2 Comments

My brother suggested I might like this blog. He was entirely right. This post truly made my day. You can not imagine simply how much time I had spent for this information! Thanks!laser marking machine price

ReplyDeleteThanks for appreciation....

Delete